Engineering Data

Conductivity of Plastics (Static Electricity Dissipation)

What is Static Electricity?

Static electricity is electricity at rest. This electrical charge is the result of a transfer of electrons that occurs due to the sliding, rubbing, turning or separating of a material, which is a prime generator of electrostatic voltages - e.g.: plastics, fiberglass, rubber, textiles, etc. Under the right conditions, this induced charge can build to 30,000 - 40,000 volts.

When this happens to an insulating material, such as a plastic, the built-up charge tends to remain in the localized area of contact. This electrostatic voltage then can discharge via an arc or spark when the plastic material comes in contact with a body at a sufficiently different potential, such as a person or microcircuit.

If electrostatic discharge (ESD) occurs to a person, the result can range from a mild shock to a very painful shock. In extreme cases, ESD could even result in the loss of life. Sparks are dangerous in an environment containing flammable liquids, solids or gases, such as in a hospital operating room, grain elevator or during the assembly of explosive devices.

Some micro-electronic parts can be destroyed or damaged by ESD as low as 20 volts. Since people are prime causes of ESD, they often cause damage to sensitive electronic parts, especially during manufacturing and assembly.

Conductive Spectrum

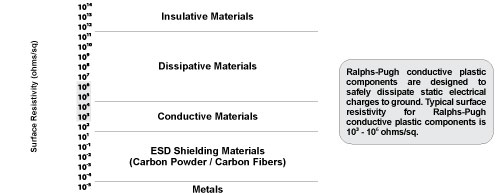

Plastics are classified as insulating materials having typical surface resistivities of 1016 - 1017 ohms/sq. The electrically conductive plastics commercially available today are composite materials of electrically insulating base resins and electrically conductive fillers or reinforcing agents. Electrical conductivity is achieved via a conductive network of particles or fibers. For electrically conductive plastics, three different conductivity ranges are defined:

- Dissipative Composites

- Conductive Composites

- ESD shielding Composites

See the chart below for the surface resistivity for the above conductivity ranges.